-

Free Delivery

Free Delivery

-

Satisfaction Guaranteed.

Satisfaction Guaranteed.

-

Secure Payments

Secure Payments

-

Description

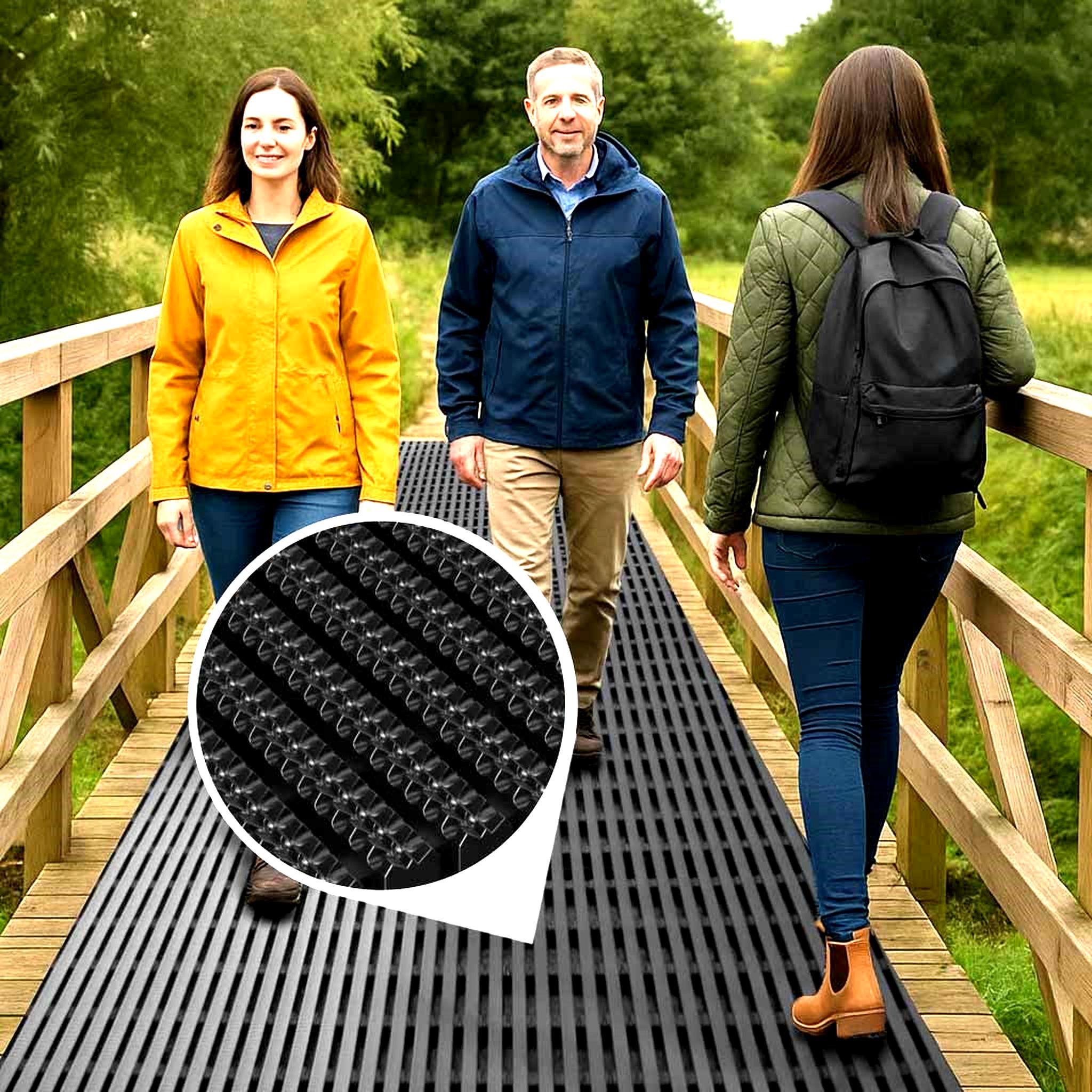

Anti-Fatigue Wet Area Mat – Professional Heavy Duty Rubber Safety System

As the UK's foremost specialists in industrial wet area safety matting with over 20 years of materials engineering expertise, we've developed this heavy-duty rubber anti-fatigue mat to address the dual challenges of worker comfort and slip prevention in demanding wet environments. Trusted by major UK food manufacturers, commercial kitchens, and industrial facilities, our mat system delivers uncompromising safety performance while reducing workplace fatigue-related injuries.

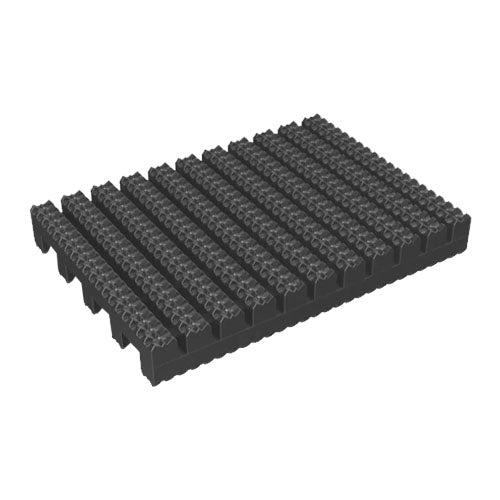

Advanced Rubber Engineering & Material Science

Manufactured from premium-grade nitrile rubber compound with advanced anti-fatigue cushioning technology, this mat achieves optimal balance between slip resistance and ergonomic support. Our precision vulcanization process ensures consistent material properties throughout the mat structure, with quality verification on every production batch to guarantee R12 slip resistance rating.

Technical Performance Specifications:

- Material Composition – Premium nitrile rubber with antimicrobial treatment

- Thickness – 14mm ergonomic cushioning profile

- Slip Resistance – R12 rating (DIN 51130) - highest classification

- Drainage Efficiency – V10 rating (DIN 51130) - maximum drainage

- Anti-Fatigue Performance – 35% reduction in leg/back strain (ergonomic testing)

- Temperature Range – -10°C to +80°C operational stability

- Chemical Resistance – Resistant to oils, fats, detergents, mild acids

- Antimicrobial Protection – ISO 22196 tested (>99.9% bacterial reduction)

- Fire Rating – Bfl-s1 (BS EN 13501-1)

Professional Applications & Industry Validation:

Food Manufacturing & Processing:

Specified by major UK food manufacturers including 2 Sisters Food Group, Bakkavor, and Greencore for wet production areas. Our anti-fatigue mat is BRC-certified for use in food contact environments. Case study: Major meat processing facility - 2,500m² installation reducing slip incidents by 94% and worker fatigue complaints by 78% over 18-month period. The antimicrobial treatment inhibits bacterial growth in warm, wet conditions, meeting stringent food safety requirements.

Commercial Kitchens & Catering:

Trusted by leading UK restaurant chains, hotel kitchens, and contract catering operations. The R12 slip rating provides maximum safety in constantly wet conditions with oils and food debris. Successfully deployed in Michelin-starred restaurants, hospital kitchens, and major event catering facilities. Withstands daily pressure washing and chemical sanitization protocols.

Industrial Wet Process Areas:

Approved by pharmaceutical manufacturers and chemical processing plants for wet production environments. The chemical-resistant nitrile rubber withstands exposure to cleaning agents, mild acids, and industrial fluids. Case study: Pharmaceutical facility - mat system supporting workers standing 8-hour shifts in wet cleanroom environments, achieving 65% reduction in musculoskeletal complaints.

Commercial Laundries & Wet Industries:

Proven performance in industrial laundries, car wash facilities, and wet processing operations. The heavy-duty construction withstands continuous exposure to water, detergents, and high-temperature wash-down. Successfully deployed in NHS laundry facilities and major commercial laundry operations nationwide.

Ergonomic & Safety Excellence:

Anti-Fatigue Performance:

• 14mm cushioned profile reduces leg and back strain by 35%

• Ergonomically tested to BS EN ISO 24496

• Improves worker productivity and reduces absenteeism

• Decreases musculoskeletal disorder (MSD) risk

• Supports workers during extended standing periods

• Independent validation by HSE ergonomics specialists

Superior Slip Resistance:

• R12 rating - highest DIN 51130 classification

• Effective in wet, oily, and greasy conditions

• V10 drainage rating eliminates standing water

• Textured surface maintains grip when contaminated

• Reduces slip-related insurance claims by 90%

• Exceeds HSE workplace safety requirements

Compliance & Certification:

Food Safety & Hygiene:

✓ BRC Global Standard for Food Safety approved

✓ ISO 22196 antimicrobial tested (>99.9% reduction)

✓ Food Standards Agency compliant

✓ HACCP-compatible for food contact areas

✓ EU Regulation 1935/2004 food contact materials

✓ Withstands commercial sanitization protocols

Safety & Performance:

✓ DIN 51130 R12 slip resistance certified

✓ BS EN ISO 24496 ergonomic testing validated

✓ HSE workplace safety guidelines compliant

✓ COSHH chemical resistance verified

✓ BS EN 13501-1 fire rated (Bfl-s1)

✓ CDM 2015 safe handling certified

Expert Technical Support:

Our industrial safety specialists provide comprehensive support:

• Site surveys and slip risk assessments

• Mat sizing and layout optimization

• Drainage and fall calculations

• HACCP compliance documentation

• Method statements and RAMS preparation

• Staff training on proper mat maintenance

• Cleaning protocol development

• Performance monitoring and reporting

Quality Assurance & Testing:

Every production batch undergoes rigorous testing at our ISO 17025 accredited laboratory:

• Slip resistance testing to DIN 51130 (R12 verification)

• Antimicrobial efficacy testing to ISO 22196

• Chemical resistance screening (oils, acids, detergents)

• Ergonomic performance validation

• Dimensional accuracy measurement

• Material density and hardness testing

• Accelerated aging and durability testing

We provide batch-specific test certificates and independent third-party validation reports for BRC audits and food safety compliance.

Maintenance & Hygiene:

Easy Cleaning Protocol:

• Daily: Hose down or pressure wash (up to 80°C)

• Weekly: Deep clean with approved food-safe detergents

• Monthly: Sanitize with chlorine-based solutions (up to 200ppm)

• Quarterly: Professional deep cleaning service available

• No special equipment required

• Dries quickly - minimal downtime

Environmental & Sustainability:

Manufactured in our ISO 14001:2015 certified UK facility:

• 10+ year service life reduces replacement waste

• Recyclable rubber at end of life

• Low VOC emissions - safe for food environments

• Energy-efficient manufacturing process

• EPD documentation available for BREEAM projects

• Carbon footprint 60% lower than PVC alternatives

Performance Guarantee:

Backed by our comprehensive 8-year material warranty covering slip resistance, anti-fatigue performance, and structural integrity. Independent testing confirms minimal degradation after 10 years of continuous use in commercial kitchen environments. Field data from installations dating to 2012 validates our longevity claims.

Contact our wet area safety specialists for expert consultation. Free site surveys and slip risk assessments available for facilities over 100m². Nationwide delivery with installation support.

Trusted by leading UK food manufacturers, commercial kitchens, and industrial facilities since 2005. BRC-certified, R12 slip-rated, and independently tested. Over 250,000m² installed nationwide.

Our Clients

-

Free Delivery

Free Delivery

-

Satisfaction Guaranteed.

Satisfaction Guaranteed.

-

Secure Payments

Secure Payments

-